GPS 100 - Introduction to Geometrical Product Specifications

An explanation of the benefits of GPS and the difference between systematic GPS and traditional tolerancing.

Any time a design has to be captured and communicated, it is done using ISO GPS. This global specification language enables a drawing of a component developed in one country to be sent to another country, where it can be understood and the component manufactured. ISO GPS is an effective communications link, even when the designer and supplier do not have a common language. It helps products to be made more easily and efficiently, using fewer resources in the process.

The course gives an overview of why tolerancing has changed over time. It explains the shortcomings of dimensional tolerancing and hybrid tolerancing where geometrical tolerancing is used as Band-Aids to try to fix dimensional tolerancing using a simple, straightforward example. Using the same example it demonstrates the advantage of systematic GPS tolerancing, where the primary tolerancing is geometrical tolerancing and dimensional tolerancing is only used to tolerance features of size. Finally, the course summarizes the advantages companies introducing systematic GPS can expect.

This is the first of a planned complete series of courses on ISO GPS (some free, some not) that will cover all aspects of the ISO GPS language, as well as a systematic procedure for applying GPS tolerancing to drawings.

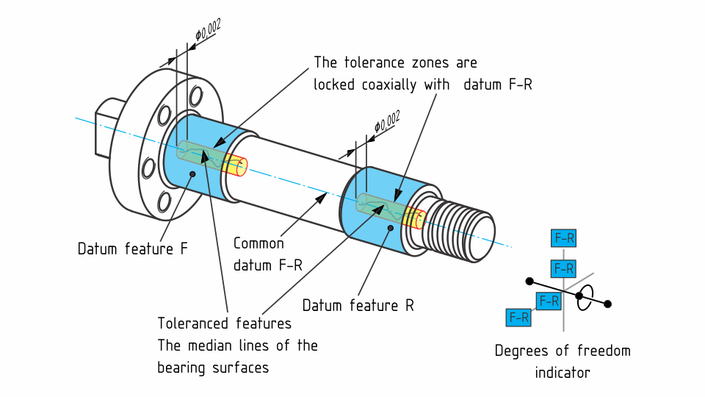

Geometrical Product Specifications (GPS) is the international symbol language used to express tolerances in technical drawings. It defines the nominal geometry of the components that make up the product, and the tolerances that quantify the allowable deviations from this nominal geometry.

Some of the more well-known ISO GPS standards are: ISO 1101 - Geometrical Tolerances, ISO 5459 - Datums, ISO 14405-1 - Size, ISO 1302 - Surface Finish and ISO 8015 - Fundamental Principles.

The ISO-GPS language is defined in a number of ISO standards developed by ISO Technical Committee 213 "Dimensional and geometrical product specifications and verification".

I have been the chairman of ISO TC 213 since 2008.

Your Instructor

Dr. Henrik S. Nielsen is the president of HN Metrology Consulting and HN Proficiency Testing, the first accredited proficiency testing provider catering to dimensional inspection and calibration laboratories in the US.

His areas of expertise include geometrical product specifications, dimensional metrology, uncertainty estimation and quality assurance for calibration laboratories. He teaches seminars on all of these subjects though various organizations.

Dr. Nielsen is the chairman of ISO Technical Committee 213 “Geometrical Product Specifications and Verification” and has been an expert serving on related committees since 1988. He has served as project leader and author of several ISO standards.

Prior to founding HN Metrology Consulting in 1998, Dr. Nielsen was the Technical Manager of Corporate Standards at Cummins Engine Co. in Columbus, Indiana. Dr. Nielsen holds a M. Sc. In Mechanical Engineering and a Ph. D. in Metrology, both from the Technical University of Denmark.

Course Curriculum

-

StartAn Overview of the Benefits of Geometrical Product Specifications (GPS) (10:20)

-

StartA Brief History of Tolerancing (14:01)

-

StartHistorical Changes in Industrial Tolerance Values (4:48)

-

StartDimensional Tolerancing (9:18)

-

StartCoaxiality Band-Aid Tolerancing (2:33)

-

StartPerpendicularity Band-Aid Tolerancing (2:01)

-

StartParallelism Band-Aid Tolerancing (1:48)

-

StartHybrid (Band-Aid) Tolerancing Conclusion (6:28)

-

StartSystematic GPS Tolerancing Part 1 (4:33)

-

StartSystematic GPS Tolerancing Part 2 (6:29)

-

StartThe Benefits of Systematic GPS Part 1 (7:36)

-

StartThe Benefits of Systematic GPS Part 2 (4:54)

-

StartThe Benefits of Systematic GPS Part 3 (5:15)

-

StartThe Benefits of Systematic GPS - Conclusion (4:32)

Frequently Asked Questions

I have learned a lot from this course. I was surprised how good it was. Before doing this course I had some knowledge and experience in metrology, but your presentation helped me to understand tolerancing in practice. Now GPS is at the top of my priority list, so I am going to get more knowledge and test it in practice.

- Tomasz Szarlowski